Properties of teflon

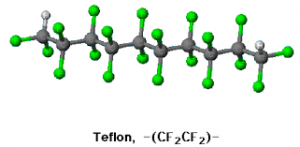

Polytetrafluoroethylene or PTFE (more commonly known as Teflon) is a particularly versatile ivory-white and opaque plastic fluoropolymer; it is made by the free-radical polymerisation of many tetrafluoroethene molecules, and is suitable for a wide range of applications in industries as diverse as aerospace, the food and drink industry, pharmaceuticals and telecoms.

Produced by AFT Fluorotec in rods or tubes of any size, or filled with glass, carbon, stainless steel or many other materials to increase wear resistance and strength, whatever your project or build, we are sure to have a material that will work for you.

THE MAIN PROPERTIES OF PTFE

If you were trying to invent a highly flexible, chemical resistant, thermal resistant, non-stick and electrically resistant material, and it hadn’t already been done, you’d be hoping you could come up with a material somewhere nearly as good as PTFE is in these areas.

PTFE’s melting point is around 327°C, and pure PTFE is almost totally chemically inert, highly insoluble in most solvents or chemicals, and thermally stable enough to be used between -200 degrees C and +260 degrees C without degrading.

Other useful PTFE properties are its high flexural strength, even in low temperatures, high electrical resistance and dielectric strength, resistance to water (owing to fluorine’s high electronegativity), and low coefficient of friction. PTFE’s density is also very high, at 2200 kg/m3.

In fact, beyond reaction to some chemical agents and solvents (for example, chlorine trifluoride, cobalt(III) fluoride, xenon difluoride or elementary fluorine if at a high pressure and temperature), the only factor to be taken into consideration when using PTFE is that it does not have a good resistance to high energy radiation, which will cause breakdown of the PTFE molecule.

MODIFIED PTFE PROPERTIES

In addition to pure PTFE, there are two co-polymers which are equally as useful as PTFE, but with some different properties.

PFA or Perfluoroalkoxy has very similar properties to PTFE in that it is very chemically resistant, flexible and thermally stable (with continuous use up to 260 degrees C), but while PTFE does have some tendency to creep, PFA is creep resistant and is excellent for melt-processing, injection moulding, extrusion, compression moulding, blow moulding, and transfer moulding.

TFM, known as PTFE-TFM, is polytetrafluoroethylene with perfluoropropylvinylether as an additional modifier, giving a denser material which is stiffer, also creep resistant like PFA, and weldable.

FILLED PTFE

Pure or virgin PTFE can deform badly under a load, but the use of fillers can help with this, though it should be noted that not all filled PTFE is suitable for use with food.

Adding a filler to PTFE can increase its strength, improve resistance to abrasion, add electrical conductivity and more; however, adding fillers can also reduce some of the advantageous PTFE properties, such as chemical resistance which will be limited by that of the filler.

Fillers used can range from glass in various percentages, stainless steel, molybdenum disulphide, carbon or graphite, depending on which properties are to be improved.

ADVANTAGES AND BENEFITS OF USING PTFE

The biggest advantage of PTFE is its versatility, and the range of applications over so many products and different industries for this material is staggering.

The use of PTFE can have massive benefits in manufacturing and engineering, not just in making tubes or liners for handling or storing corrosive chemicals, but by coating parts such as bearings or screws to increase the lifetime of both the parts themselves and the machinery they are part of.

A PTFE-coated screw will be resistant to corrosion, due to PTFE’s ability to repel water and oil, and lubricated by the material to smoothly drive into whatever surface you are fastening to, with reduced friction, resulting in less wear on both the screw and the surface, and a longer-lasting, more secure finish.

Friction and wear can also be factors with bearings, and a PTFE coat can give the same benefits as with coating screws, with the additional advantage that the coating will also be heat-resistant.

It’s clear that longer lasting, higher-performance parts can add to the efficiency of any machinery, reduce the need to constantly acquire replacement parts, both saving money and the time needed to fit the replacements, as well as reducing waste. This will also reduce maintenance needs as there are less likely to be faults with the equipment, and also greatly reduce, or even eliminate, any expensive manufacturing downtime due to faults or repairs.

Cleaning of equipment can also be reduced in some cases as a PTFE coat is non-wetting, facilitating self-cleaning of parts.

And Teflon textile finishes can even help the environment, because, when applied to fabric, the finish will repel water and oil stains, reducing the need to use dry cleaning, and fabrics will also dry more quickly, using less energy with tumble drying, and last longer due to reduced wear.

With the added advantages that PTFE is non-toxic, has only a minor contraindication for humans from polymer fume fever (only if the temperature of any Teflon-coated pans reaches 260 degrees C) and is FDA approved and food-safe, this material really is of great benefit in many different areas.

USES OF PTFE

Most people have never heard of PTFE industrial coating, but when you mention Teflon, a look of understanding passes easily on their faces. PTFE (Polytetrafluoro Ethylene) is the technical name of the material, and it’s commonly sold under the Teflon brand name, which is manufactured by DuPont. Dr. Roy Plunkett, a researcher who worked at DuPont, is credited with developing PTFE industrial coating in the late 1930s.

At the time of his discovery, he was actually trying to create a new refrigerant. During the course of development, he noticed that the gas inside the bottle he was using actually stopped flowing out before the bottle should have been empty. He sawed the bottle open and discovered that the inside was coated with the non-stick material we now know as Teflon. His contribution has changed the face of plastic manufacturing forever.

Teflon is probably best-known for its role as the non-stick surface inside cookware. This is because PTFE industrial coating is one of the most slippery materials that’s in existence today. In addition to being slippery, the material also brings a number of other features to the table, offering high temperature resistance, little reaction to most chemicals, and reduced stress cracking and corrosion. These features make Teflon perfect for numerous applications, including:

- Cookware– As already mentioned, the slippery surface created by Teflon makes it perfect for cookware. Many brands offer lines of cookware that are coated with PTFE in order to prevent food from sticking to the pots and pans. This reduces the need for cooking oil because these pots and pans are naturally non-stick.

- Nail polish– That smooth surface that doesn’t crack is often achieved through the use of PTFE industrial coating.

- Hair styling tools– Hair straighteners and curling irons are often coated with Teflon because of the high temperatures emitted by these tools.

- Windshield wiper blades– There are numerous applications for PTFE industrial coating within the automotive industry as well. The blades of windshield wipers are the most notable because the smooth surface enables them to glide smoothly across the windshield.

- Fabric and carpet protection– Stains are less likely to stick to carpets or fabrics that have been treated with PTFE industrial.

- Chemical and steel industries– Hoses and other machine parts commonly handle some highly corrosive substances that sometimes are transferred at extremely high temperatures. PTFE industrial coating is one of the best materials to handle this type of use because it addresses all of the problems that are otherwise caused by working with chemicals or steel. Every type of hose will deteriorate over time, but those that are made of PTFE industrial coating will do so much more slowly than those made of other materials because of the many features of the material.